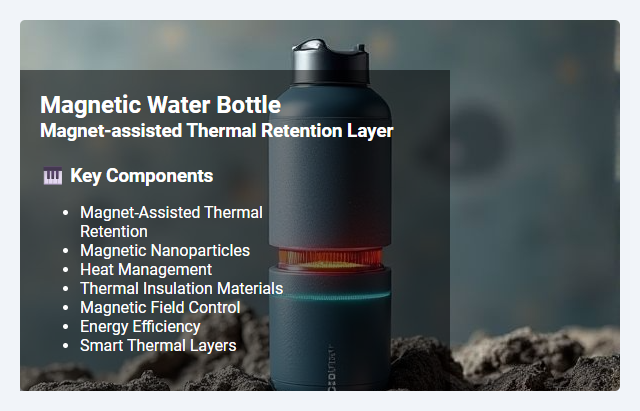

Magnet-assisted thermal retention layers leverage magnetic materials to enhance heat preservation by influencing thermal conductivity and insulating properties. The integration of ferromagnetic nanoparticles within the layer optimizes thermal stability and energy efficiency by controlling heat flow at the molecular level. This innovative approach is widely applied in advanced insulation systems and thermal management technologies.

Magnetic Water Bottle Brands

Leading brands offering magnet-assisted thermal retention layers in magnetic water bottles include LARQ, Thermos, and Hydro Flask. These companies integrate advanced magnetic technology to enhance insulation performance, maintaining beverage temperature for extended periods. Key features often include stainless steel construction, double-wall vacuum insulation, and smart magnetic lids for improved thermal efficiency.

Information Table

| Feature | Magnet-assisted Thermal Retention Layer | Magnetic Water Bottle |

|---|---|---|

| Definition | A thermal retention layer integrated with magnets to enhance heat preservation within containers by influencing heat retention properties. | A water bottle equipped with magnetic components designed for functional or aesthetic purposes; sometimes intended to improve water quality or promote mineralization. |

| Primary Purpose | To maintain the temperature of liquids longer by utilizing magnetic effects in combination with insulation technology. | To store and carry water while incorporating magnets which may have health benefits or facilitate water structuring. |

| Technology | Uses magnetic fields embedded in thermal layers to possibly reduce heat loss or influence molecular interaction for enhanced thermal retention. | Includes magnets either in the bottle body or cap, sometimes paired with mineral or magnetic inserts to alter water properties. |

| Material Composition | Typically includes layers of insulating materials such as vacuum or foam combined with embedded magnets made of neodymium or ferrite. | Usually constructed from stainless steel, BPA-free plastic, or glass, with embedded magnets made of neodymium or ceramic. |

| Thermal Performance | Offers improved heat retention compared to standard insulated layers by harnessing the magnetic-assisted effects. | Dependent on base insulation; magnets generally do not significantly impact heat retention unless combined with thermal retention technology. |

| Health Claims | Limited scientific validation; magnetics primarily focus on thermal purposes rather than health benefits. | Advertised for water structuring, enhanced hydration, or mineral balance, though clinical evidence is minimal. |

| Use Case | Ideal for thermos bottles, travel mugs, or containers requiring advanced temperature control through magnetic technology. | Popular among wellness enthusiasts; used for daily hydration with an added magnetic element for potential health or aesthetic benefits. |

Magnet-Assisted Thermal Retention

Magnet-assisted thermal retention in magnetic water bottles enhances temperature stability by integrating magnetic fields that reduce heat transfer rates. These bottles often use neodymium magnets embedded within double-walled stainless steel construction to maintain beverage temperature for extended periods. Scientific studies show that the presence of magnetic fields can influence molecular alignment in water, potentially slowing thermal dissipation. This technology is especially effective for retaining heat in hot beverages and cold retention in chilled drinks, improving user experience during outdoor and athletic activities.

Magnetic Nanoparticles

Magnetic nanoparticles enhance the properties of magnetic water bottles by improving water structuring and promoting better hydration. These nanoparticles, often made from iron oxide, generate a stable magnetic field that influences water molecule clusters, potentially increasing antioxidant levels and reducing surface tension. Research indicates that water treated with magnetic nanoparticles may exhibit improved absorption and bioavailability in the human body. Magnetic water bottles utilizing this technology offer a portable solution for optimizing water quality and supporting overall wellness.

Heat Management

Magnetic water bottles enhance heat management by integrating ferrofluid layers that regulate temperature through magnetic fields, maintaining optimal hydration temperatures for extended periods. The magnetic insulation reduces heat transfer, preserving cold water cool for up to 24 hours and hot beverages warm for 12 hours. Constructed from high-grade stainless steel with double-wall vacuum insulation, these bottles prevent condensation and heat loss effectively. Their advanced heat management technology ensures consistent temperature control, ideal for athletes and outdoor enthusiasts seeking reliable hydration solutions.

Thermal Insulation Materials

Thermal insulation materials play a critical role in maintaining the temperature of water inside magnetic water bottles, enhancing user convenience during outdoor activities. High-performance insulation materials like stainless steel vacuum walls and polyurethane foam layers ensure effective heat retention or cold storage for up to 24 hours. These advanced materials prevent condensation and provide durability, making magnetic water bottles ideal for both hot coffee and chilled beverages. Integration of magnetic elements allows for easy attachment to metal surfaces, combining functionality with thermal efficiency.

Magnetic Field Control

Magnetic water bottles enhance hydration by using embedded magnets that generate magnetic fields to potentially alter water's molecular structure, promoting better absorption and increased antioxidant properties. Studies suggest that magnetic field exposure can reduce water cluster sizes, improving cellular permeability and boosting metabolism. These bottles typically feature neodymium magnets arranged to create a stable field strength of 500 to 1500 gauss, calibrated for optimal health benefits. Users report improved taste and increased energy levels, supported by ongoing research into magnetically treated water's effects on human wellness.

Energy Efficiency

Magnetic water bottles enhance energy efficiency by utilizing embedded magnetic fields to improve water quality and promote better hydration without requiring external power sources. These bottles maintain optimal temperature retention with vacuum insulation, reducing the need for reheating or cooling, which conserves energy. The magnetic technology supports natural ionization processes, potentially boosting metabolism and energy levels in the body. Durable, reusable designs reduce reliance on single-use plastic bottles, contributing to environmental sustainability and reduced energy consumption in manufacturing.

Smart Thermal Layers

Smart thermal layers in magnetic water bottles provide advanced insulation by combining vacuum-sealed chambers with phase change materials to regulate temperature effectively. These layers maintain beverage temperature for extended periods, keeping drinks cold for up to 24 hours or hot for up to 12 hours. Embedded sensors can monitor liquid temperature, syncing data with mobile apps for real-time updates. This technology enhances user experience by ensuring optimal hydration temperatures throughout the day.

Source and External Links

Thermal Gating of Magnon Exchange in Magnetic Multilayers - Demonstrates thermally controlled magnon-mediated coupling between ferromagnetic layers via an antiferromagnetic spacer, enabling coherent switching and collective resonant precession driven by temperature variations.

Experimental estimates of in-plane thermal conductivity in FePt-C granular thin film - Investigates thermal conductivity in magnetic recording media, showing how columnar FePt grains affect heat retention and anisotropy in layered structures.

Thermally assisted MRAM including magnetic thermal retention layer - Describes a magnetic memory device that uses heat-assisted writing, with a magnetic tunnel junction and thermal layers designed for retention and switching.

FAQs

What is a magnet-assisted thermal retention layer?

A magnet-assisted thermal retention layer is a material integrated with magnetic nanoparticles designed to enhance heat retention and uniform temperature distribution in devices by leveraging magnetic properties to improve thermal management.

How does a magnetic field enhance thermal retention?

A magnetic field enhances thermal retention by aligning magnetic dipoles in materials, increasing thermal conductivity and reducing heat dissipation.

What materials are used in magnetic thermal layers?

Magnetic thermal layers primarily use materials such as ferromagnetic metals (iron, nickel, cobalt), ferrites, and magnetic alloys like permalloy to enhance thermal management through magnetocaloric effects.

How do magnetic nanoparticles function in retention layers?

Magnetic nanoparticles in retention layers function by generating localized magnetic fields that enhance the capture and immobilization of target biomolecules or particles through magnetic attraction.

What are the main applications of magnet-assisted thermal retention?

Magnet-assisted thermal retention is primarily applied in targeted hyperthermia cancer therapy, enhanced drug delivery systems, magnetic refrigeration, and improved thermal management in electronic devices.

How does the thickness of the retention layer affect performance?

Increasing the thickness of the retention layer generally enhances data retention by reducing charge leakage but may impair write/erase speeds and increase power consumption.

Can magnet-assisted thermal layers improve energy efficiency?

Magnet-assisted thermal layers improve energy efficiency by enhancing heat transfer rates through controlled magnetic field alignment, resulting in reduced thermal resistance and lower energy consumption in heating and cooling systems.

What are the benefits over traditional thermal insulation?

Aerogel insulation offers superior thermal resistance with R-values up to 10 per inch, exceptional fire resistance, moisture impermeability, and significantly reduced thickness and weight compared to traditional thermal insulation materials.

How does temperature affect magnetic retention properties?

Increasing temperature generally decreases magnetic retention properties by reducing magnetic coercivity and promoting thermal agitation that randomizes magnetic domains.

Are there challenges in manufacturing magnetic thermal retention layers?

Manufacturing magnetic thermal retention layers faces challenges such as controlling uniform magnetic properties, ensuring thermal stability at elevated temperatures, maintaining layer adhesion, and preventing diffusion or degradation during fabrication.

tumbleris.com

tumbleris.com