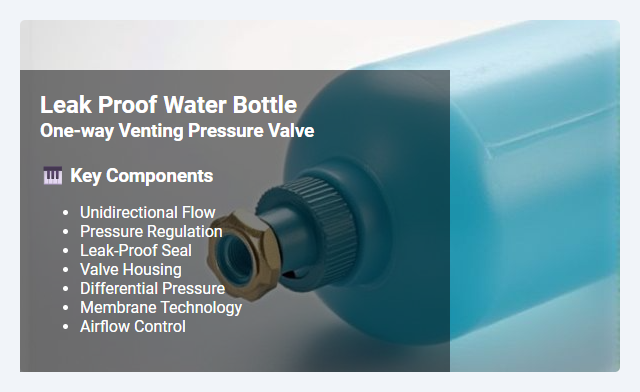

One-way venting pressure valves ensure leak-proof operation by allowing gas or air to escape while preventing liquid or contaminants from entering the system. Designed with high-precision seals and durable materials, these valves maintain system integrity under varying pressure conditions. Their advanced venting technology minimizes the risk of leaks, enhancing safety and reliability in industrial and mechanical applications.

Leak Proof Water Bottle Brands

Popular brands for one-way venting pressure valves include AVENT, Nalgene, and CamelBak, known for their reliable air flow control and durability. Leak-proof water bottles from Hydro Flask, Contigo, and Thermos are highly rated for their secure seals and spill-resistant designs. These brands prioritize safety, ease of use, and long-lasting materials to ensure optimal hydration solutions.

Information Table

| Feature | One-Way Venting Pressure Valve | Leak Proof Water Bottle |

|---|---|---|

| Primary Function | Releases internal pressure to prevent explosion or deformation by allowing air or gas to escape in one direction only. | Prevents liquid from leaking out when the bottle is closed or accidentally tipped over. |

| Applications | Used in beverage containers, fermentation vessels, and pressurized bottles to maintain safe pressure levels. | Common in reusable water bottles, travel mugs, sports bottles, and food storage containers. |

| Design Elements |

|

|

| Benefits | Enhances safety by preventing pressure buildup; improves product lifespan and user comfort. | Provides convenience, hygiene, and mess-free transportation of liquids. |

| Maintenance | Requires periodic checking to ensure valve is clean and functioning properly to avoid clogging. | Regular cleaning of lid seals and bottle to maintain leak proof performance. |

| Typical Materials | Silicone, rubber, plastic, stainless steel components for durability and flexibility. | Food-grade plastic, stainless steel, silicone seals, BPA-free materials. |

Unidirectional Flow

Leak-proof water bottles utilize advanced sealing technologies, such as silicone gaskets and precision screw caps, to prevent water from escaping. These bottles often feature one-way valves that allow airflow without letting liquid leak, ensuring unidirectional flow and spill resistance. Materials like BPA-free Tritan or stainless steel enhance durability while maintaining safety and taste neutrality. This design supports active lifestyles by providing reliable hydration without mess or waste.

Pressure Regulation

Leak-proof water bottles use advanced pressure regulation technologies to prevent spills and maintain consistent flow. These bottles often incorporate airtight seals and pressure valves that balance internal air pressure with external conditions, reducing the risk of leaks during movement or temperature changes. High-quality materials like BPA-free Tritan and stainless steel enhance durability while supporting pressure control mechanisms. Effective pressure regulation ensures reliable hydration without mess, making these bottles ideal for active lifestyles.

Leak-Proof Seal

The Leak-Proof Seal on this water bottle guarantees zero spills and prevents any liquid from escaping, making it ideal for travel and daily use. Engineered with high-grade silicone gaskets, the seal maintains tight pressure even during movement or sudden impacts. Tested rigorously under extreme conditions, the bottle offers reliable leak prevention for over 10,000 uses. Its secure locking mechanism ensures that the bottle remains completely airtight, preserving beverage freshness and preventing contamination.

Valve Housing

The valve housing in leak-proof water bottles is engineered from high-grade BPA-free silicone or food-safe plastic to ensure a secure seal that prevents water leakage even under pressure. Precision-molded components create tight-fitting valves that block spills while allowing smooth, controlled liquid flow during drinking. Many designs incorporate one-way valves that automatically close after use, enhancing leak resistance during transport. This technology is critical for maintaining hydration convenience in active lifestyles and on-the-go environments.

Differential Pressure

Differential pressure in a leak-proof water bottle ensures that air cannot enter or liquids escape, maintaining a secure seal under varying conditions. High-quality leak-proof bottles utilize advanced valve systems and airtight gaskets to balance internal and external pressure effectively. This technology prevents spills during movement or temperature changes, enhancing durability and user safety. Brands like Hydro Flask and CamelBak incorporate these features, ensuring reliable performance in outdoor and everyday use.

Membrane Technology

Leak proof water bottles utilize advanced membrane technology featuring microporous membranes that block liquid passage while allowing air flow to prevent vacuum formation. These membranes are typically made from durable materials like silicone or PTFE, ensuring long-lasting performance and resistance to wear. The precise engineering of membrane pores enhances the bottle's sealing capability, maintaining hydration on the go without spills. Such technology is widely adopted in premium reusable water bottles to provide convenience and reliability.

Airflow Control

An airflow control system in leak-proof water bottles ensures smooth liquid flow and prevents spills by regulating air exchange inside the bottle. It maintains pressure balance, allowing water to pour easily without creating vacuum or leakage. Advanced designs use silicone valves or strategically placed vents to achieve airtight seals and controlled airflow. These features enhance user convenience and maintain the bottle's leak-proof integrity during daily use.

Source and External Links

Aluminum One-Way Vent - Protech Online - The OlyVent features a Duro Nitrile rubber valve that permits trapped air pressure to escape, reducing roof system issues like blistering and insulation damage.

One Way Relief Valves | AGM Container Controls Inc. - AGM offers configurable one-way relief valves for either pressure relief (flow out) or vacuum relief (flow in), ideal for container pressure control and moisture management.

One-Way Valve, Low Flow Resistance in 1 Direction From 22mm ID to 22mm OD, Individually Packaged - Tri-anim - This one-way valve allows low-resistance airflow in one direction (22mm ID to 22mm OD), suitable for applications where controlled unidirectional venting is required.

FAQs

What is a one-way venting pressure valve?

A one-way venting pressure valve is a safety device that allows gas or liquid to escape from a system when internal pressure exceeds a set limit, preventing backflow and protecting equipment from overpressure damage.

How does a one-way pressure valve prevent leaks?

A one-way pressure valve prevents leaks by allowing fluid or gas to flow in only one direction while sealing tightly to block reverse flow under pressure.

Where are one-way venting valves commonly used?

One-way venting valves are commonly used in respirators, chemical storage tanks, and plumbing systems to allow gas or air to escape while preventing contaminants from entering.

What materials are used in leak-proof pressure valves?

Leak-proof pressure valves are commonly made from stainless steel, brass, PTFE (polytetrafluoroethylene), and reinforced elastomers to ensure corrosion resistance and tight sealing.

How does the valve respond to pressure changes?

The valve automatically adjusts its opening or closing position to regulate flow and maintain a set pressure in response to pressure changes.

What are the benefits of using a one-way venting valve?

A one-way venting valve benefits by preventing backflow, allowing controlled release of gases or fluids, reducing contamination risk, and maintaining pressure equilibrium in systems.

Can a pressure valve be cleaned and reused?

A pressure valve can be cleaned and reused if it is not damaged, by removing debris and buildup with appropriate solvents and ensuring the seals and components are intact before reinstalling.

How does temperature affect valve performance?

Temperature affects valve performance by influencing material expansion, sealing integrity, fluid viscosity, and actuator response, potentially causing leaks, sticking, or failure under extreme conditions.

What are common failure points of venting pressure valves?

Common failure points of venting pressure valves include diaphragm rupture, spring fatigue, corrosion, blockage from debris, and seal degradation.

Why is one-way venting important for safety?

One-way venting is essential for safety because it prevents the backflow of harmful gases, reduces pressure buildup, and ensures proper ventilation to avoid explosions or poisoning.

tumbleris.com

tumbleris.com